Blog

When History Turns Humid: Solving Mold Issues in Boston’s Historic Buildings

Boston is known for its rich history, cobblestone streets, and centuries-old architecture. But while historic homes and buildings offer charm and character, they also present a unique challenge – humidity and mold growth. As the fall season arrives, cooler nights and damp weather can create the perfect environment for mold to thrive, especially in older […]

Why Mold Removal Is a Must for Your Boston Home This Fall

The crisp air of fall is starting to settle across Boston. Many homeowners are busy pulling out sweaters, decorating with pumpkins, and preparing their homes for the colder months ahead. But one issue often overlooked during this seasonal shift is mold growth. Fall creates the perfect storm for mold problems – cooler weather, damp conditions, […]

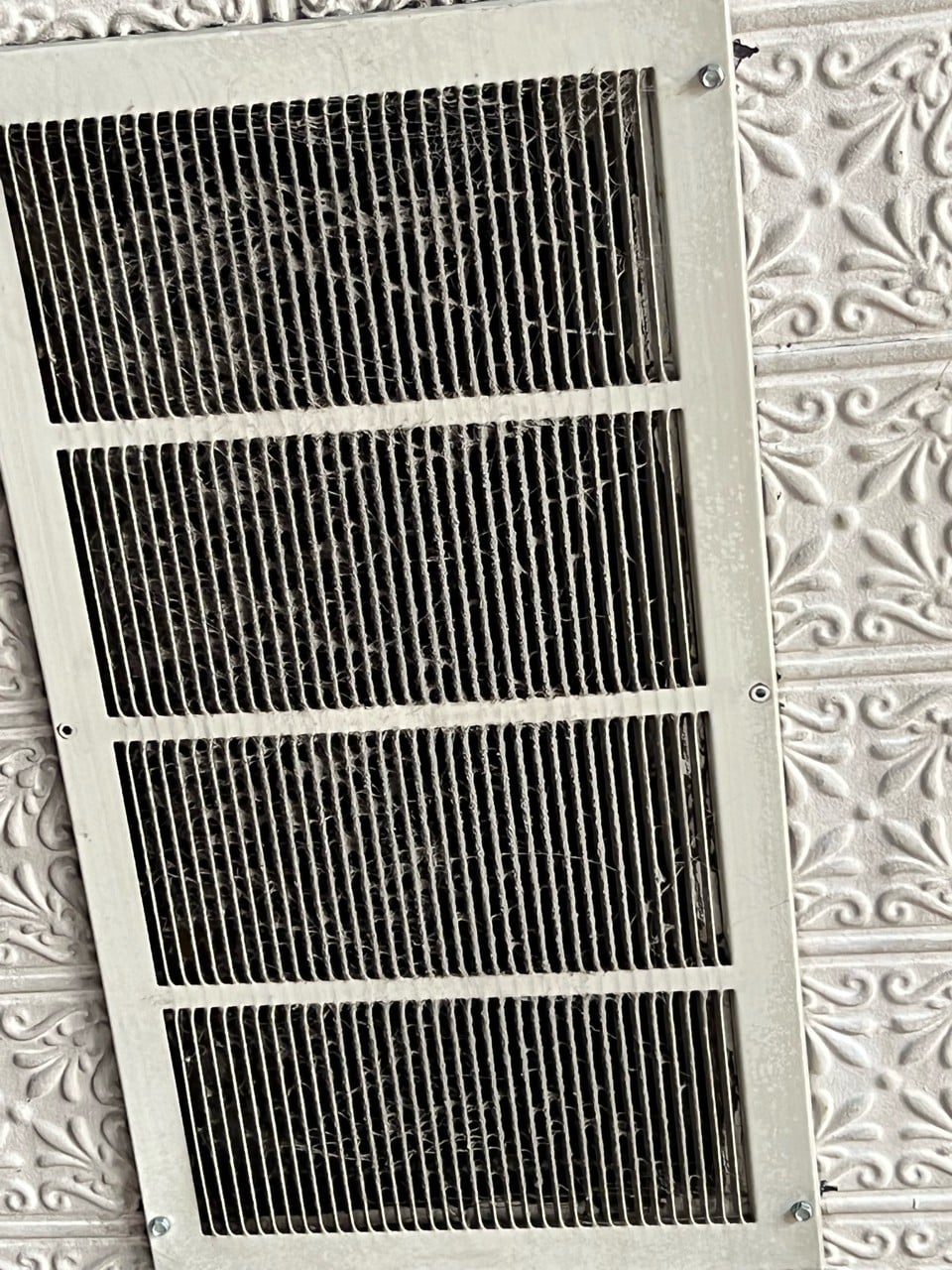

Top 5 Warning Signs of Mold Growth and When to Call a Professional

Mold is sneaky. It hides behind drywall, creeps into crawlspaces, and—even worse—takes refuge in your air ducts. Often, you don’t see it… until the problem becomes significant or shows up in your health, comfort, or home’s structure.At Aspen Air Duct Cleaning, serving the Greater Boston area for years, we’ve helped countless homeowners identify and fix […]

The Hidden Dangers of Skipping Mold Testing After Water Damage

Water damage is among the most overwhelming challenges homeowners in the Greater Boston area may encounter. Whether it’s from a burst pipe, basement flood, roof leak, or storm runoff, water intrusion can wreak havoc on your home. But here’s something many homeowners don’t realize: the visible water damage is just the beginning.What you can’t see—mold […]

Top 10 Signs It’s Time for Insulation Removal and Replacement

Your home’s insulation is one of those silent heroes—it works behind the scenes, keeping you cozy in the winter and cool in the summer, all while helping you save on energy bills. But like any part of your house, insulation doesn’t last forever. Over time, it can lose its effectiveness, get damaged, or even cause […]

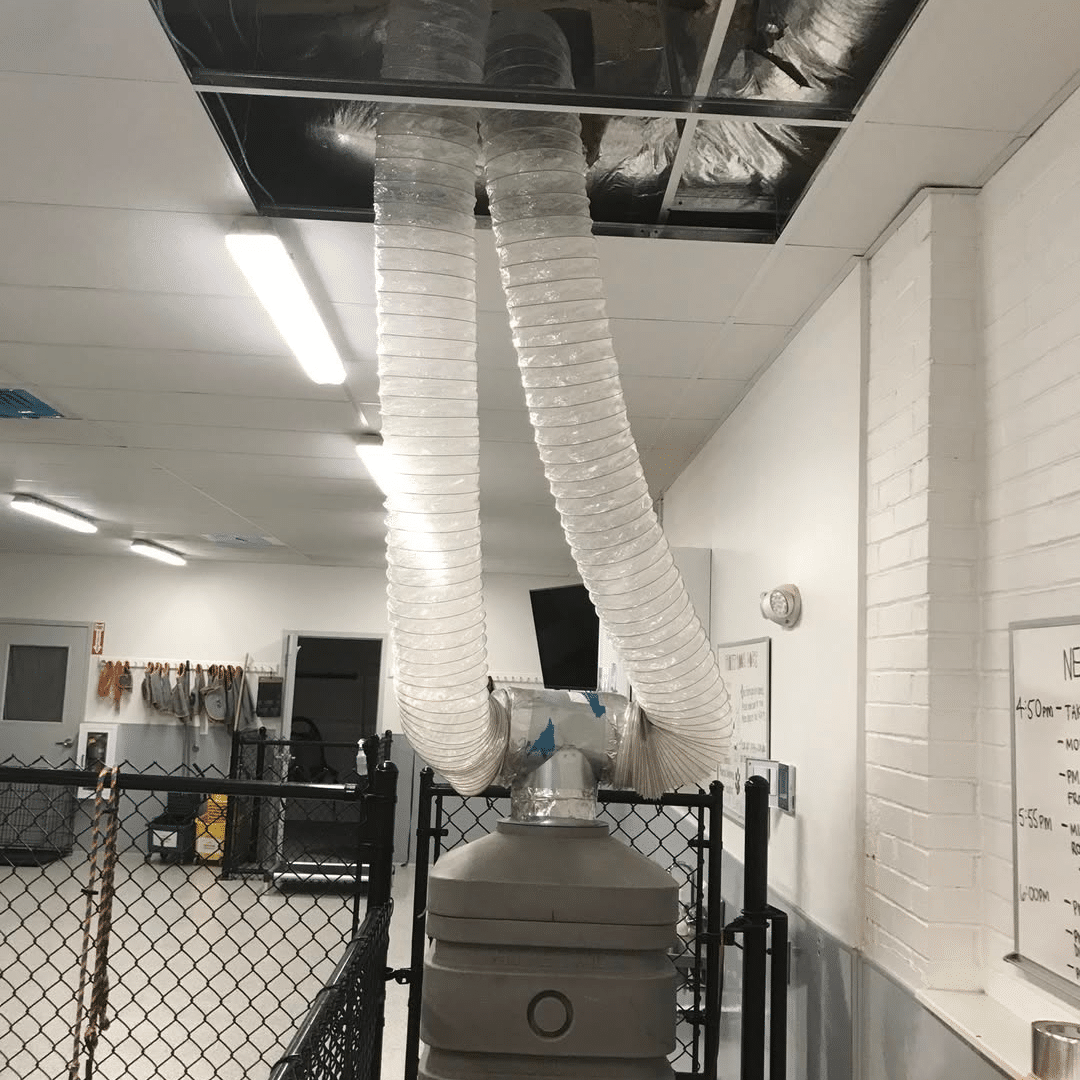

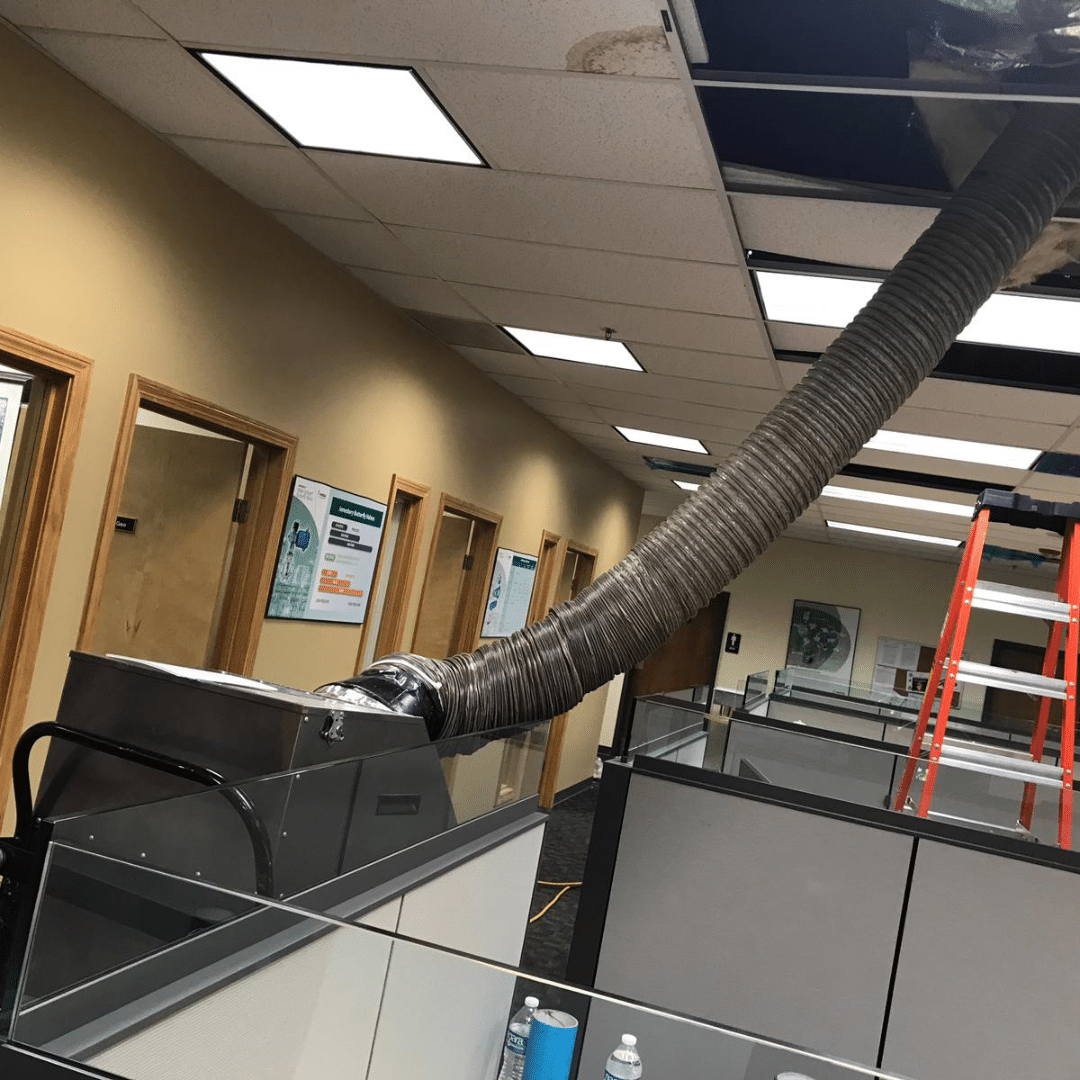

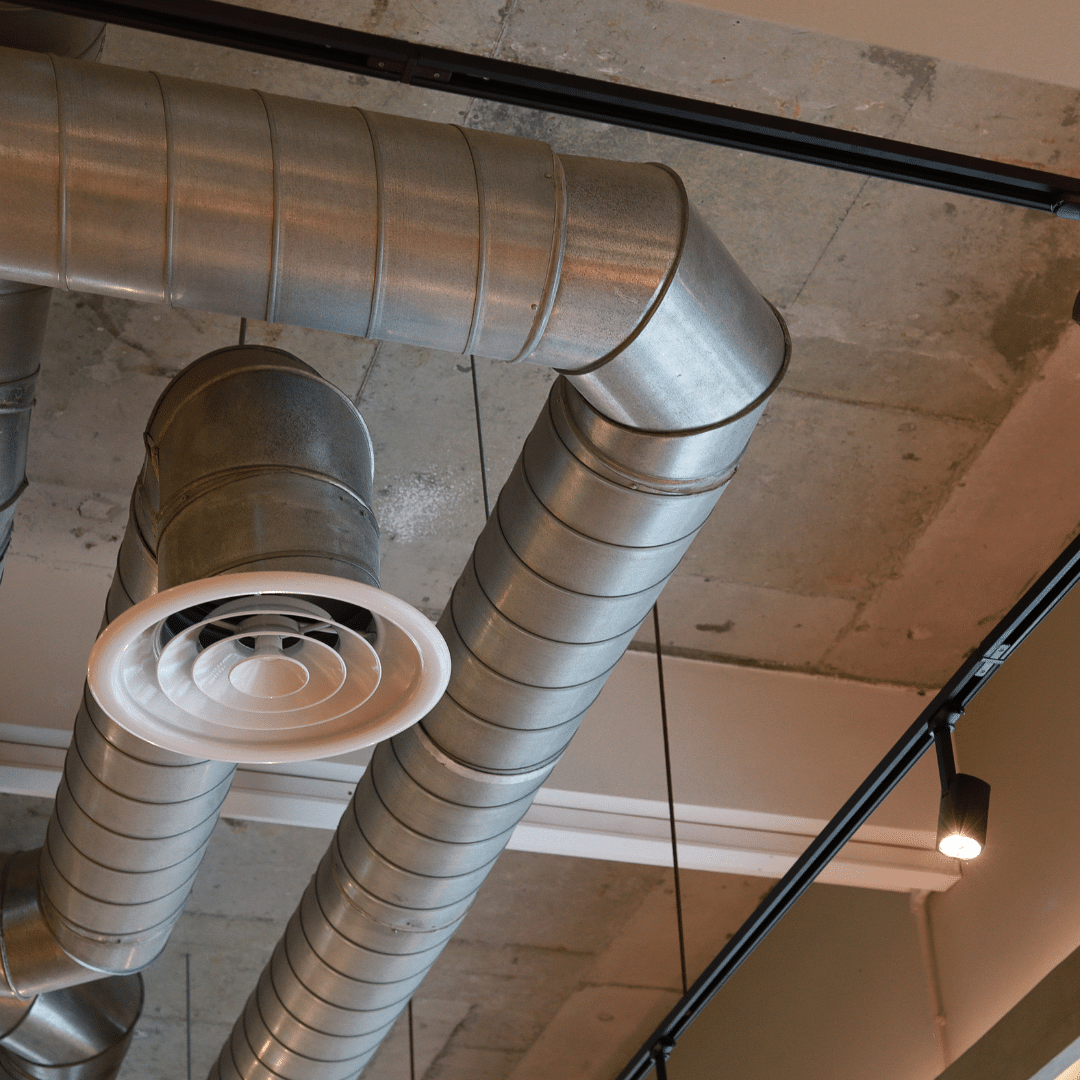

The Importance of Commercial Air Duct Cleaning for Office Buildings and Commercial Spaces

As a business owner or property manager, you’re always looking for ways to make your space more efficient, healthier, and more comfortable for your employees, tenants, and clients. But have you ever considered how something as simple as your air ducts can affect the overall atmosphere of your office building or commercial space? If not, […]

How Aeroseal Improves Your Home’s Air Quality

Spring’s finally here – and while the blooming flowers and longer days are a welcome sight, the season also brings along its fair share of sneezes and sniffles. If you’re already bracing yourself for allergy season, you’re not alone. But here’s something you might not realize: your home’s air ducts could be making things worse. […]

How Aeroseal Duct Sealing Can Make Your Home More Energy-Efficient This Year

When homeowners think about energy efficiency, they often focus on upgrading appliances, installing new insulation, or switching to energy-efficient windows. However, one of the most overlooked sources of energy waste is your home’s duct system. If your ducts have leaks, they can allow significant amounts of heated or cooled air to escape, forcing your HVAC […]

Seasonal Allergies? Why Air Duct Cleaning Could Be Your Best Defense

Seasonal allergies can feel like a constant battle—sneezing, itchy eyes, congestion, and fatigue can make it hard to enjoy the beauty of spring and fall. While many allergy sufferers focus on outdoor triggers like pollen, one significant cause is often overlooked: the air circulating inside your home. If you’re searching for a way to reduce […]

Why Air Duct Cleaning Matters: 5 Ways It Improves Air Quality and Home Efficiency

Air duct cleaning is often neglected, yet it plays a crucial role in maintaining a healthy and energy-efficient home. However, it plays a crucial role in ensuring your indoor air quality is at its best while improving the overall performance of your HVAC system. Cleaning your air ducts is an investment in the efficiency of […]