Blog

HERS Index Rater 101: Your Gateway to Energy-Efficient Homes

In today’s world, where sustainability and energy efficiency are becoming increasingly vital, understanding the HERS Index Rater and what it means for your home can be highly beneficial. Aspen Air Duct Cleaning is HERS-rated and dedicated to helping you create a healthier and more efficient living environment. That’s why we believe it’s essential to shed […]

The Longevity of Commercial Aeroseal Solutions

As the chilly winds of winter give way to the milder breezes of spring in Methuen, MA, homeowners begin to think about home improvements and maintenance tasks to ensure their homes are comfortable, energy-efficient, and ready for the changing seasons. One often overlooked but incredibly impactful service to consider this March is Aeroseal duct sealing. […]

Maximize Methuen Home Efficiency with Aeroseal This March

As the chilly winds of winter give way to the milder breezes of spring in Methuen, MA, homeowners begin to think about home improvements and maintenance tasks to ensure their homes are comfortable, energy-efficient, and ready for the changing seasons. One often overlooked but incredibly impactful service to consider this March is Aeroseal duct sealing. […]

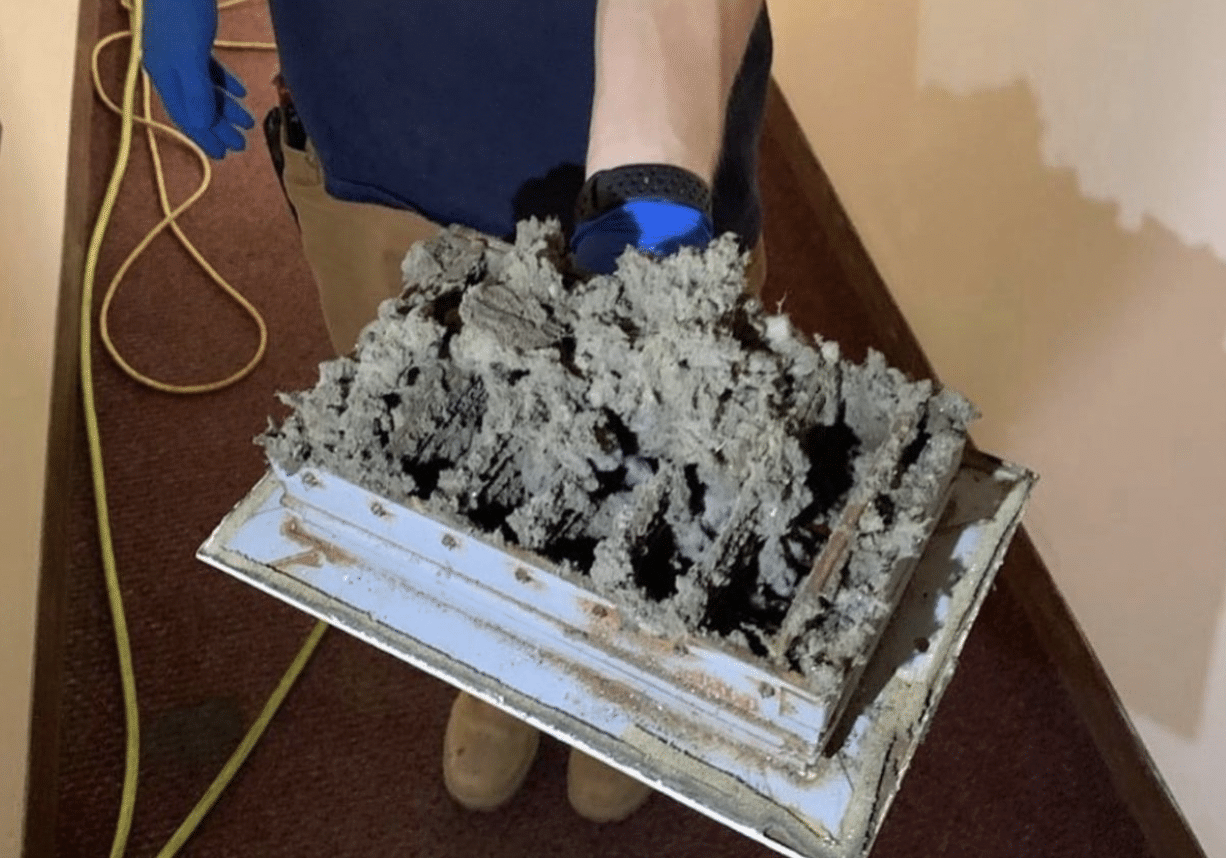

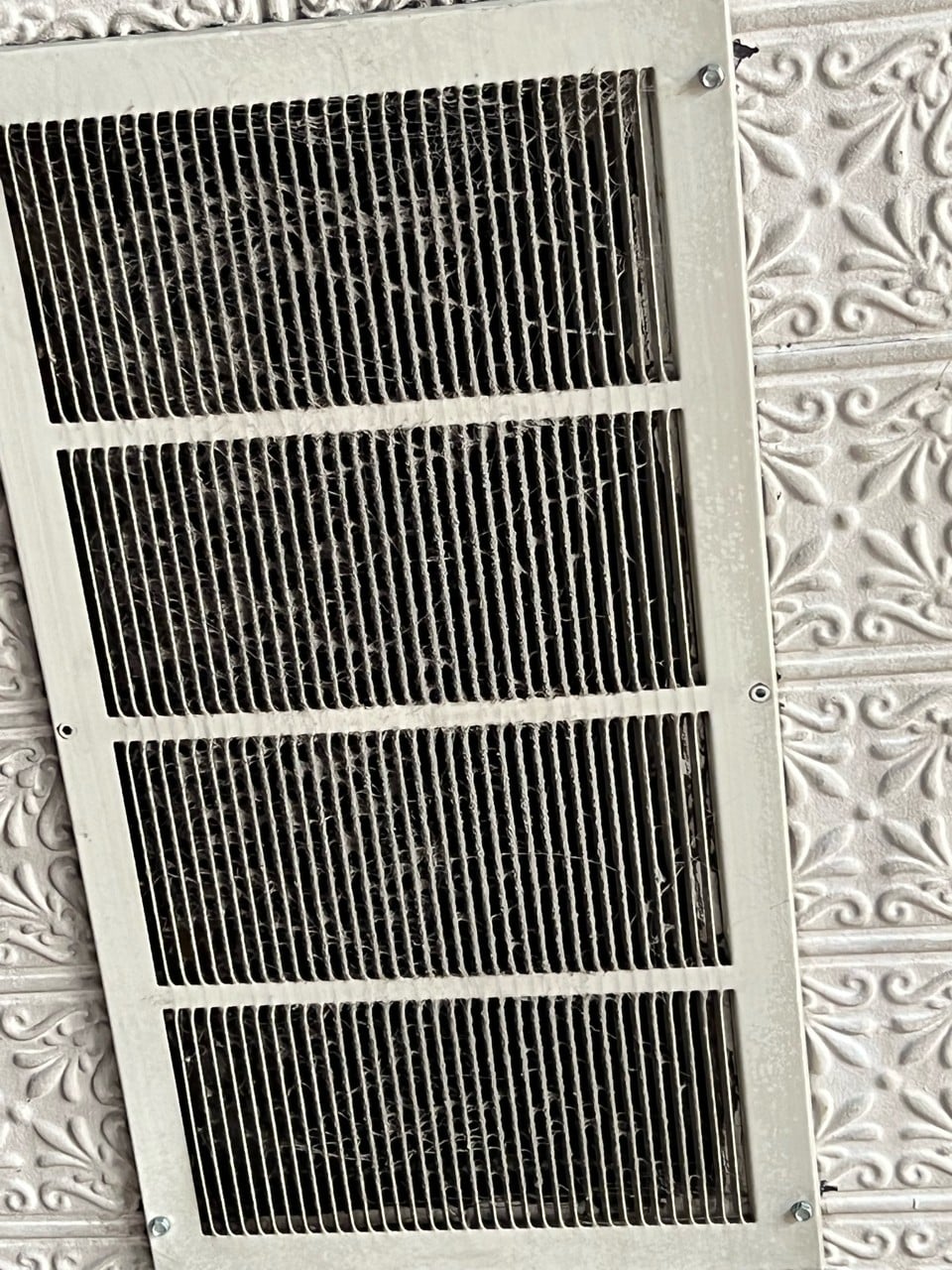

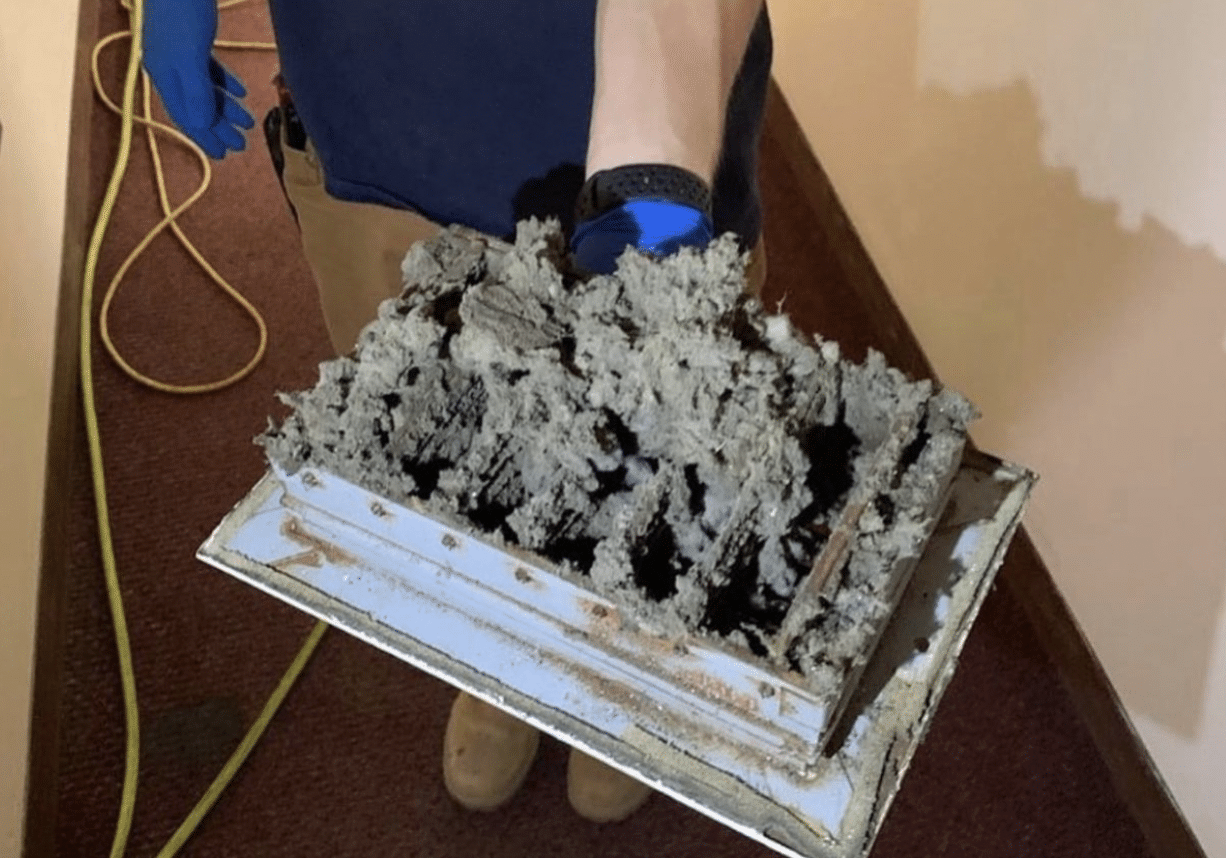

7 Signs Your Air Ducts Need Attention

Curious about the air quality in your home? Your air ducts might have a message for you! In this blog post, we’ll discuss the seven clear signs that your air ducts are in need of some tender loving care. From strange odors to inconsistent airflow, these indicators can be subtle but impactful. Join us as […]

Is Air Duct Cleaning a Waste of Money?

Indoor air quality has become a common concern for homeowners, prompting many to explore avenues to enhance the air they breathe within their homes. One such avenue is air duct cleaning, a service that claims to improve the efficiency of HVAC systems and, consequently, the quality of indoor air. But the question remains: Is air […]

Top 5 Problems of Poor Quality Air in Homes and their Solutions

Step into a world where the air you breathe matters more than you might think. In this blog, we’ll discuss the often overlooked challenges associated with poor indoor air quality—the silent culprits impacting our homes. From allergens to pollutants, discover the top five problems that might be compromising the air you and your loved ones […]

10 Expert Steps on How to Safely Remove Mold from Walls

Mold can be a persistent and unsightly problem that plagues many homes, particularly on walls. If left untreated, it can not only damage your walls but also pose health risks to your family. However, the good news is that removing mold from walls doesn’t have to be an overwhelming task. In this blog, we’ll explore […]

Save Money and Breathe Easier: The Benefits of Commercial Air Duct Cleaning

Maintaining a clean and healthy workspace is essential for anyone’s success. One often-overlooked aspect of a clean working environment is the condition of your commercial air ducts. Proper air duct maintenance is not only vital for the health and well-being of your employees, but also for the longevity of your HVAC system. In this article, […]

Does Mold Have to be Removed Professionally?

Discovering mold in your living spaces can be concerning, and the question that often arises is whether you truly need a mold professional to address the issue. At Aspen Duct Cleaning, we firmly believe that when it comes to mold, professional inspection, and remediation are not just recommended but essential. In this comprehensive guide, we […]

Mold Removal and Home Insurance: What You Need To Know

When it comes to protecting your home and investment, homeowners insurance plays a crucial role in providing coverage for various types of damages. One such concern that homeowners may encounter is mold damage. Mold can be a persistent and harmful issue, leading to property damage and potential health risks. In this comprehensive guide, we will […]